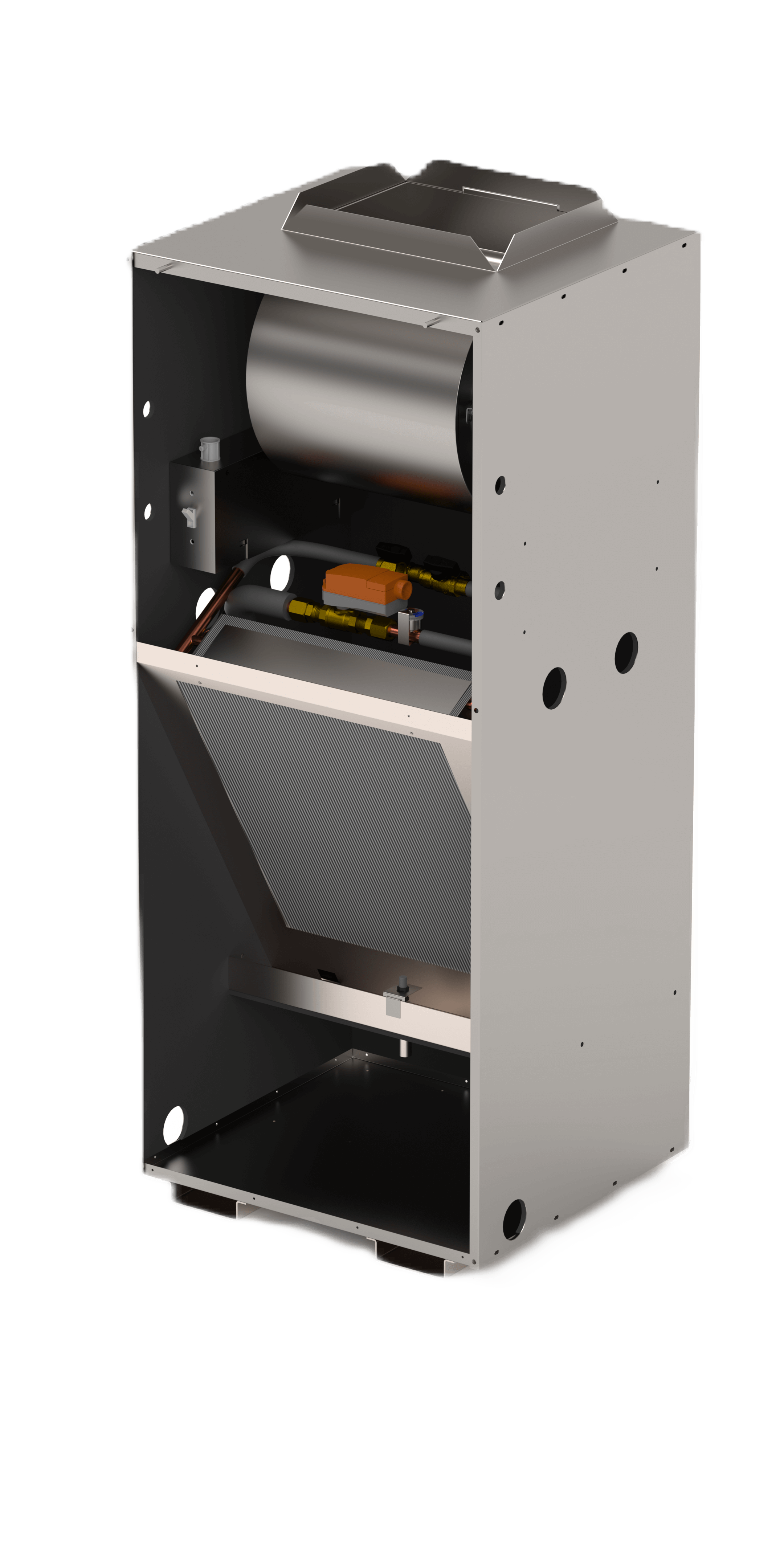

Vertical Fan Coil

BTR Series

Aurum’s BTR Series is our replacement solution for outdated blow through fan coil units. By maintaining the core functionality of the original system, Aurum has enhanced the basic operations of a vertical fan coil unit to deliver improved energy efficiency, airflow and overall comfort. This slide-in chassis is engineered for a straightforward, non-invasive replacement.

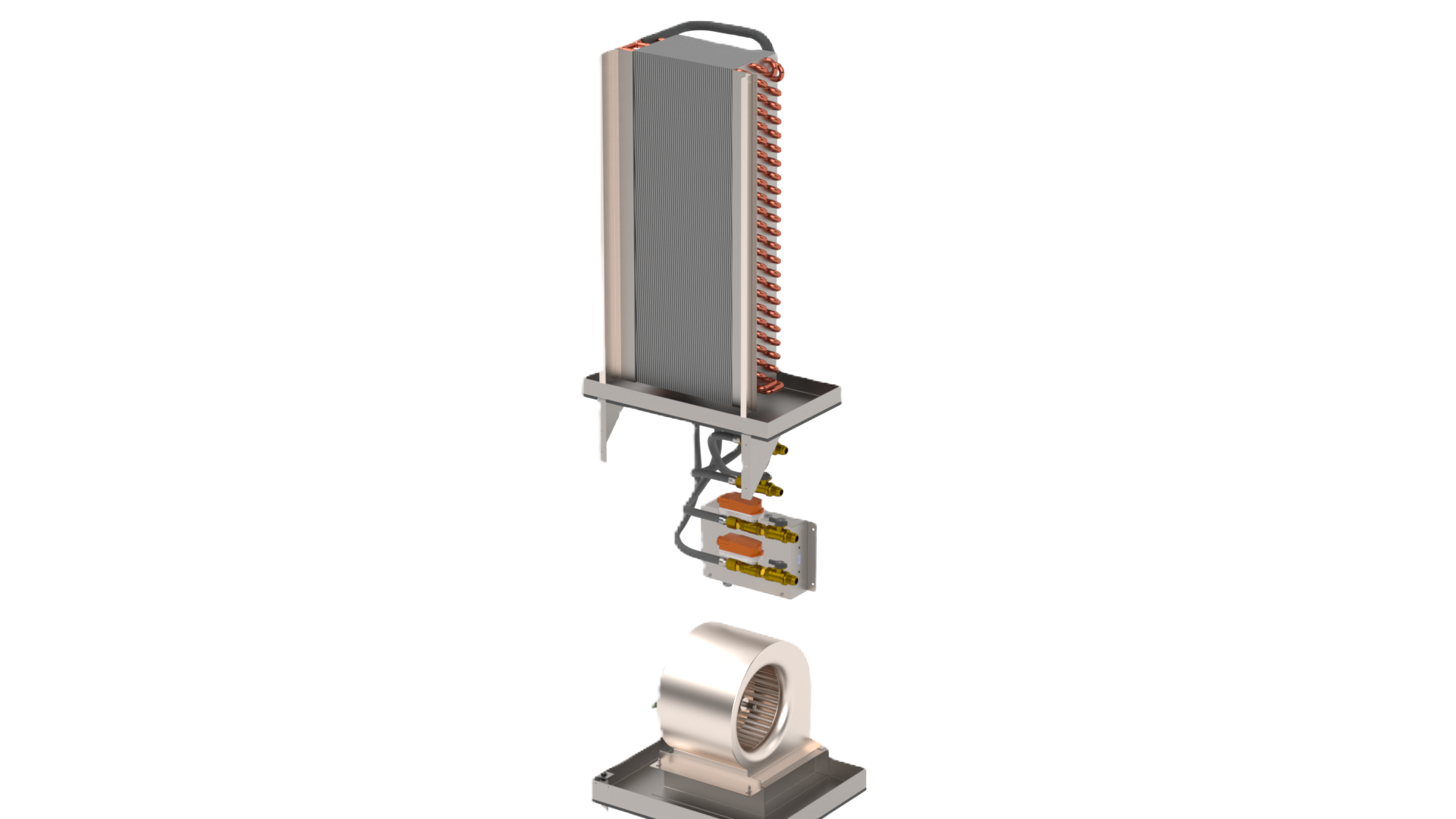

Coil

Aurum Manufacturing’s coils are manufactured with type L copper tubing, aluminum fins and stainless-steel side rails. All coils are brazed for maximum strength. Copper piping is insulated to prevent sweating in summer months. Prior to delivery all coils go through pressure tests and visual inspection. Coils are customizable for job specifications and/or to meet building configurations. (ie. Allowing for an upwards supply feed).

Chassis

The BTR series Chassis is assembled with 100% 20-guage stainless steel material. The interior of the chassis is insulated with closed cell insulation to prevent moisture buildup and reduce noise from vibrations. The dimensions of the chassis vary with different BTR Series models, as can be seen in the products dimension chart

Fan Blower

Aurum offers a variety of different motors and blowers. Sizes are dependent on required specifications and conditions for each fan coil unit. Offered motors and blowers, included but not limited to: EC motors (standard) Variable speed motor PSC motor

Drain Pan

The BTR series drain pan is assembled with 100% 20-gauge stainless steel material to virtually eliminate the possibility of rust growth. All corners of the drain pan are welded. The drain pan is positively sloped to allow for quick and effective drainage. The bottom of the drain pan is also insulated to prevent condensation and reduce vibration noises.

Union Connections

These fittings make for easy installation and future serviceability.

Control Valve and Actuator

The BTR series drain pan is assembled with 100% 20-gauge stainless steel material to virtually eliminate the possibility of rust growth. All corners of the drain pan are welded. The drain pan is positively sloped to allow for quick and effective drainage. The bottom of the drain pan is also insulated to prevent condensation and reduce vibration noise Aurum offers flexibility in control valves options include: Power open / power close Normally open/ normally closed Spring return Modulating

Control Centre

Our control box is designed for easy accessibility for future service. Aurum offers a variety of control options to meet building requirements and exceed industry standards. Options include, but are not limited to: Heat only – cool only Heat and cool 2 pipe Heat and cool 4 pipe Heat and cool, with auxiliary heater 2 pipe Modulating/ variable speed

You may also like...